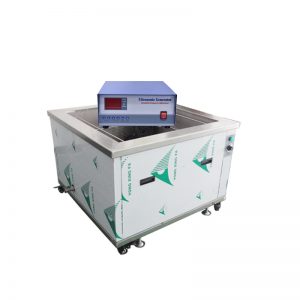

High frequency ultrasonic cleaning machine, an efficient and environmentally friendly cleaning equipment, has been widely used in various industrial fields and has become an indispensable part of modern industry. It utilizes the vibration and cavitation effects of ultrasound to instantly generate countless tiny bubbles in the cleaning solution. These bubbles rapidly expand and burst, exerting a powerful cleaning force to easily remove dirt and oil from the surface of the cleaned item.

Compared with traditional cleaning methods, the advantages of high-frequency ultrasonic cleaning machines are self-evident. প্রথমত, its cleaning efficiency is extremely high, and it can complete a large number of cleaning tasks in a short period of time, greatly improving production efficiency. Secondly, due to the action of ultrasound, the cleaning solution can penetrate into the tiny gaps and holes of the cleaned item, completely removing those difficult to reach dirt, ensuring the thoroughness and comprehensiveness of the cleaning effect. In addition, high-frequency ultrasonic cleaning machines also have the characteristics of energy conservation and environmental protection, which can effectively reduce energy consumption and the use of chemical agents during the cleaning process, meeting the requirements of modern industrial sustainable development.

It is precisely these significant advantages that make high-frequency ultrasonic cleaning machines highly favored among many enterprises. More and more enterprises are realizing that using high-frequency ultrasonic cleaning machines can not only improve production efficiency and product quality, but also reduce production costs and environmental pollution. It is a cleaning solution with long-term development potential.

|

Model |

Internal size |

Outsize mm |

কম্পাঙ্ক (Khz) |

শক্তি(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||

অতিস্বনক ট্রান্সডুসার,অতিস্বনক জেনারেটর,অতিস্বনক ক্লিনার -SKSONIC

অতিস্বনক ট্রান্সডুসার,অতিস্বনক জেনারেটর,অতিস্বনক ক্লিনার -SKSONIC