Ultrasonic vibration rods also have the advantages of easy operation and maintenance. Operators only need to set the appropriate ultrasonic frequency and power based on the material characteristics and extraction requirements to achieve automated production. Meanwhile, the cleaning and maintenance of the equipment are relatively simple, reducing the operating costs of the enterprise. With the continuous advancement of biotechnology and the expanding oil market, the application prospects of ultrasonic vibration rods in the field of oil extraction are becoming increasingly broad. In the future, we can expect this technology to further expand into more oil crops and oil products, injecting new vitality into the development of the biotechnology industry. Ultrasonic vibration rod manufacturers in the biotechnology industry are also constantly innovating and improving their products. They are committed to developing more efficient, energy-saving, and intelligent devices to meet the constantly changing demands of the market. In this context, ultrasonic vibration rods will undoubtedly become an important tool in the field of oil extraction in the biotechnology industry, helping enterprises achieve sustainable development and green production.

Ultrasonic vibration rods also have the advantages of easy operation and maintenance. Operators only need to set the appropriate ultrasonic frequency and power based on the material characteristics and extraction requirements to achieve automated production. Meanwhile, the cleaning and maintenance of the equipment are relatively simple, reducing the operating costs of the enterprise. With the continuous advancement of biotechnology and the expanding oil market, the application prospects of ultrasonic vibration rods in the field of oil extraction are becoming increasingly broad. In the future, we can expect this technology to further expand into more oil crops and oil products, injecting new vitality into the development of the biotechnology industry. Ultrasonic vibration rod manufacturers in the biotechnology industry are also constantly innovating and improving their products. They are committed to developing more efficient, energy-saving, and intelligent devices to meet the constantly changing demands of the market. In this context, ultrasonic vibration rods will undoubtedly become an important tool in the field of oil extraction in the biotechnology industry, helping enterprises achieve sustainable development and green production.

|

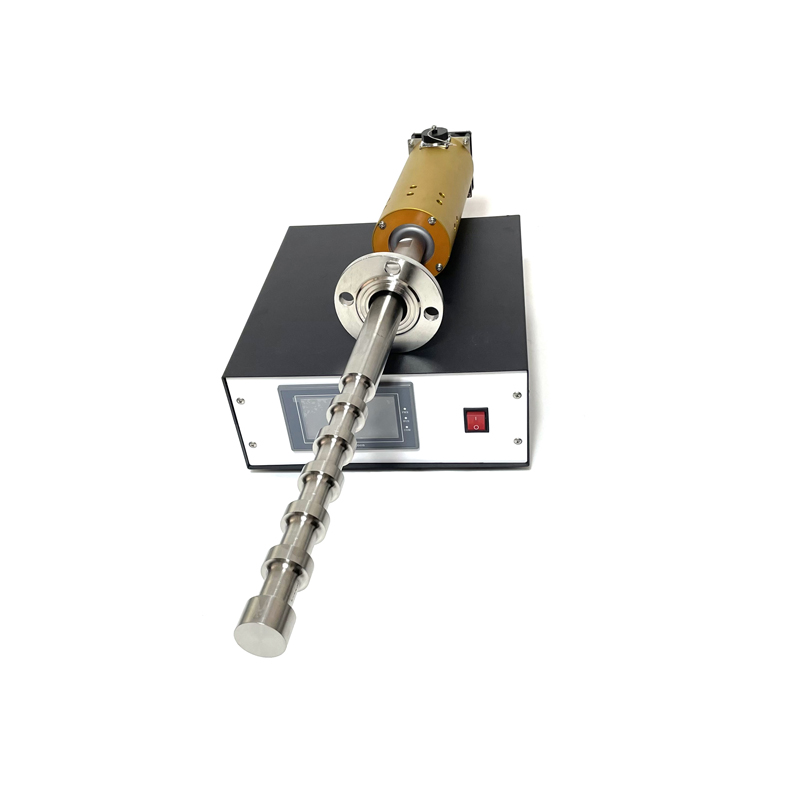

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|