Ultrasonic biodiesel emulsification refers to the process of uniformly mixing immiscible oil-water liquids under cavitation to form a dispersed system, in which one liquid is evenly distributed in another liquid to form an emulsion. Emulsification, separation, synthesis and degradation of water in fuel oil, and production of biodiesel to save fuel and reduce exhaust pollution. After adding ultrasonic waves to the vibration rod during the reaction process of ultrasonic biodiesel emulsification treatment, the reaction rate is 30% Кому 60%, the esterification reaction temperature is reduced by 20% Кому 60%, and the amount of methanol used is reduced by 10% Кому 30%. В то же время, the separation of glycerol is accelerated because the amount of methanol used is reduced.

Ultrasonic biodiesel emulsification refers to the process of uniformly mixing immiscible oil-water liquids under cavitation to form a dispersed system, in which one liquid is evenly distributed in another liquid to form an emulsion. Emulsification, separation, synthesis and degradation of water in fuel oil, and production of biodiesel to save fuel and reduce exhaust pollution. After adding ultrasonic waves to the vibration rod during the reaction process of ultrasonic biodiesel emulsification treatment, the reaction rate is 30% Кому 60%, the esterification reaction temperature is reduced by 20% Кому 60%, and the amount of methanol used is reduced by 10% Кому 30%. В то же время, the separation of glycerol is accelerated because the amount of methanol used is reduced.

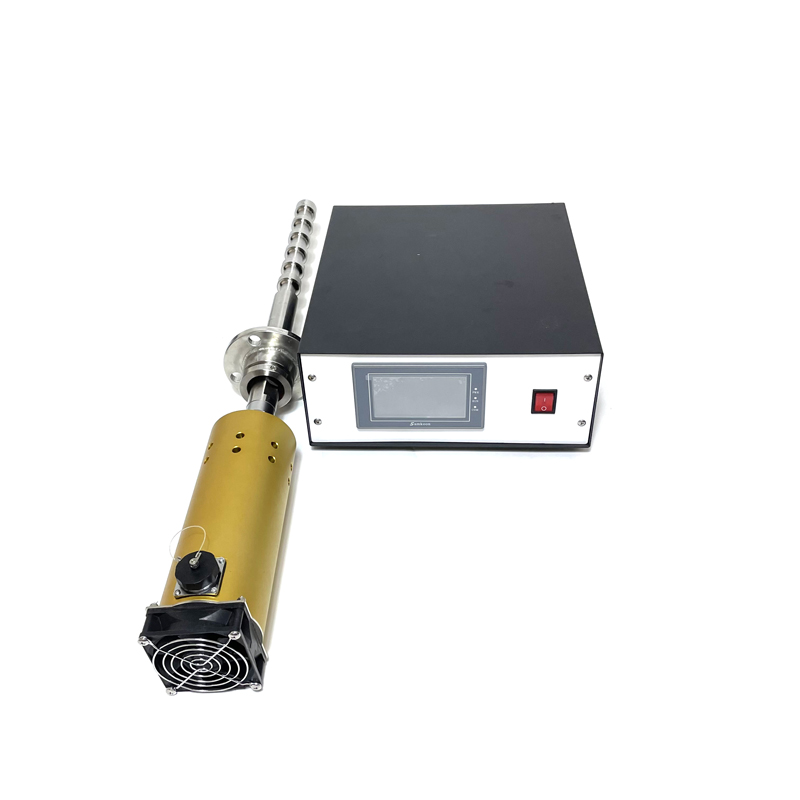

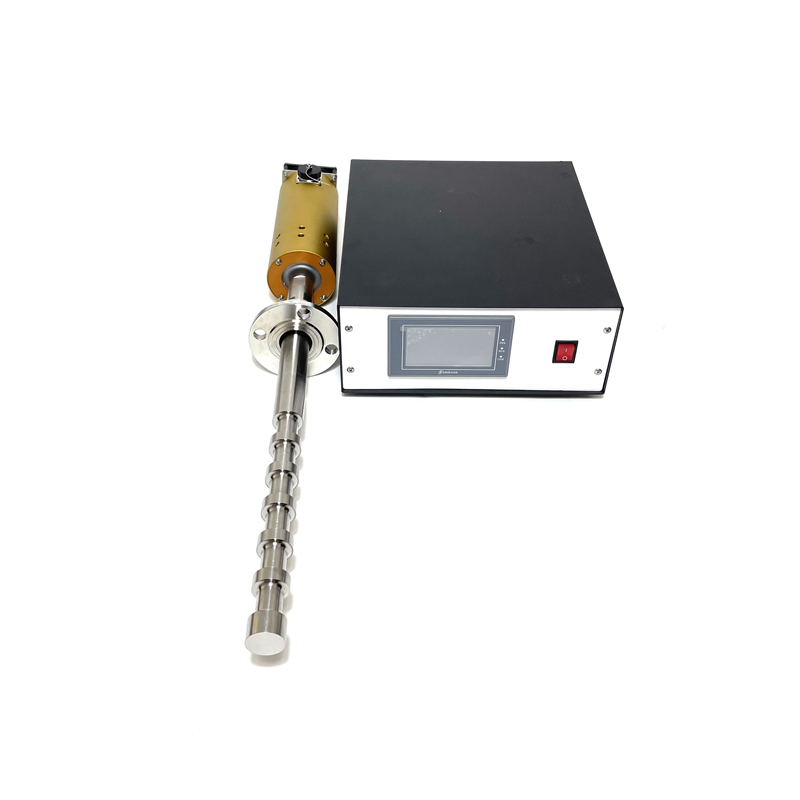

Ultrasonic biodiesel emulsification treatment vibration rod can be used to accelerate dissolution, reaction, oil emulsification, and prevent inner wall scaling. The large-scale continuous ultrasonic biodiesel equipment for oil-water emulsification can control the type of emulsion; The power required for lotion production is small; The formed lotion is more stable; Low temperature treatment, good biological activity; Can handle high viscosity materials.

Ultrasonic waves generate alternating high and low pressures in exposed liquids. During the low-pressure cycle, ultrasound generates vacuum bubbles in the liquid, and during the high-pressure cycle, the real bubbles rupture violently, a phenomenon known as cavitation. The implosion of cavitation bubbles causes strong fluid dynamic shear forces. Shear force can fully mix the reactants and shorten the reaction time. To prepare oil in water lotion, its limit sound intensity is much lower than that of water in oil lotion. The type of sound field affects the emulsification process by applying a certain traveling wave. Compared to applying some stationary waves, the process efficiency is improved.

|

Tubular Equipment

Тип

|

Tubular Transducer

Тип

|

Частота

(КГц)

|

Ultrasound

Output(W)

|

Total Length

(миллиметр)

|

Diameter

(миллиметр)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ультразвуковой преобразователь,Ультразвуковой генератор,Ультразвуковой очиститель -SKSONIC

Ультразвуковой преобразователь,Ультразвуковой генератор,Ультразвуковой очиститель -SKSONIC