In the design and application of industrial ultrasonic generator cleaning power supply, an important aspect that cannot be ignored is the stability and efficiency optimization of the power supply. With the advancement of technology, modern industry increasingly demands higher precision and efficiency in cleaning operations, and ultrasonic cleaning technology has gradually become the preferred choice for many industries due to its unique non-contact, high-efficiency, and environmentally friendly characteristics.

In the design and application of industrial ultrasonic generator cleaning power supply, an important aspect that cannot be ignored is the stability and efficiency optimization of the power supply. With the advancement of technology, modern industry increasingly demands higher precision and efficiency in cleaning operations, and ultrasonic cleaning technology has gradually become the preferred choice for many industries due to its unique non-contact, high-efficiency, and environmentally friendly characteristics.

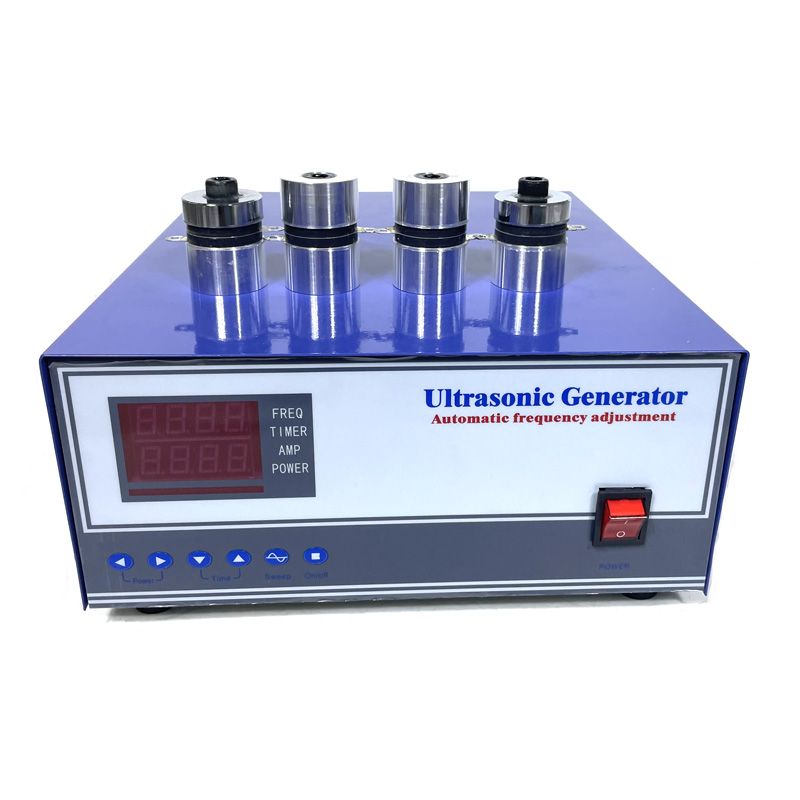

In order to further improve the performance of ultrasonic cleaning power supplies, research and development personnel are committed to introducing advanced power electronic control technologies, such as PWM (Pulse Width Modulation) and PID (Proportional Integral Derivative) closed-loop regulation systems, to achieve more accurate power output control. These technologies can not only effectively reduce energy loss and improve energy conversion efficiency, but also automatically adjust the ultrasonic frequency and power according to the characteristics of the cleaning object, ensuring the optimal cleaning effect.

Intelligence and networking have also become new trends in the development of industrial ultrasonic generator cleaning power supplies. By integrating IoT technology, cleaning equipment can remotely monitor its operating status, provide real-time feedback on cleaning effectiveness, and even automatically adjust working parameters according to preset programs, greatly improving the convenience and flexibility of production management. Meanwhile, the intelligent data analysis function can also help users accurately analyze key indicators such as energy consumption and efficiency during the cleaning process, providing strong support for production optimization. Industrial ultrasonic generator cleaning power supply will develop towards a more efficient, intelligent, and environmentally friendly direction. We look forward to seeing more innovative technologies applied, bringing revolutionary changes to the industrial cleaning field and driving the entire industry towards a greener and more sustainable development path.

|

Mataqali |

Power(W) |

iTuvatuva (KHz) |

Transducer numbers |

Size |

|

AC110V60HZ+/-10% USA /LATIN AMERICA STANDARD ARE AVAILABLE |

||||

|

PLS-QXDY-300 |

300W |

17khz,20khz,25khz,28khz,33khz,40khz |

3-6 |

300x360x150 |

|

PLS-QXDY-600 |

600W |

17khz,20khz,25khz,28khz,33khz,40khz |

6-12 |

300x360x150 |

|

PLS-QXDY-900 |

900W |

17khz,20khz,25khz,28khz,33khz,40khz |

9-18 |

300x360x150 |

|

PLS-QXDY-1000 |

1000W |

17khz,20khz,25khz,28khz,33khz,40khz |

10-20 |

300x360x150 |

|

PLS-QXDY-1200 |

1200W |

17khz,20khz,25khz,28khz,33khz,40khz |

12-24 |

300x360x150 |

|

PLS-QXDY-1500 |

1500W |

17khz,20khz,25khz,28khz,33khz,40khz |

15-30 |

300x360x150 |

|

PLS-QXDY-1800 |

1800W |

17khz,20khz,25khz,28khz,33khz,40khz |

18-36 |

300x360x150 |

|

PLS-QXDY-2000 |

2000W |

17khz,20khz,25khz,28khz,33khz,40khz |

20-40 |

300x360x150 |

|

PLS-QXDY-2400 |

2400W |

17khz,20khz,25khz,28khz,33khz,40khz |

24-48 |

300x360x150 |

|

PLS-QXDY-3000 |

3000W |

17khz,20khz,25khz,28khz,33khz,40khz |

50-60 |

300x360x150 |

|

High Frequency |

300W-1200W |

54KHZ,60KHZ,68KHZ,70KHZ,80KHZ,100KHZ,120KHZ,135KHZ |

||

|

High Frequency |

100W-300W |

175-200KHZ |

||

|

Above ultrasonic generator 110V-120V or 220V-240V are available,contact with us during |

||||

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC