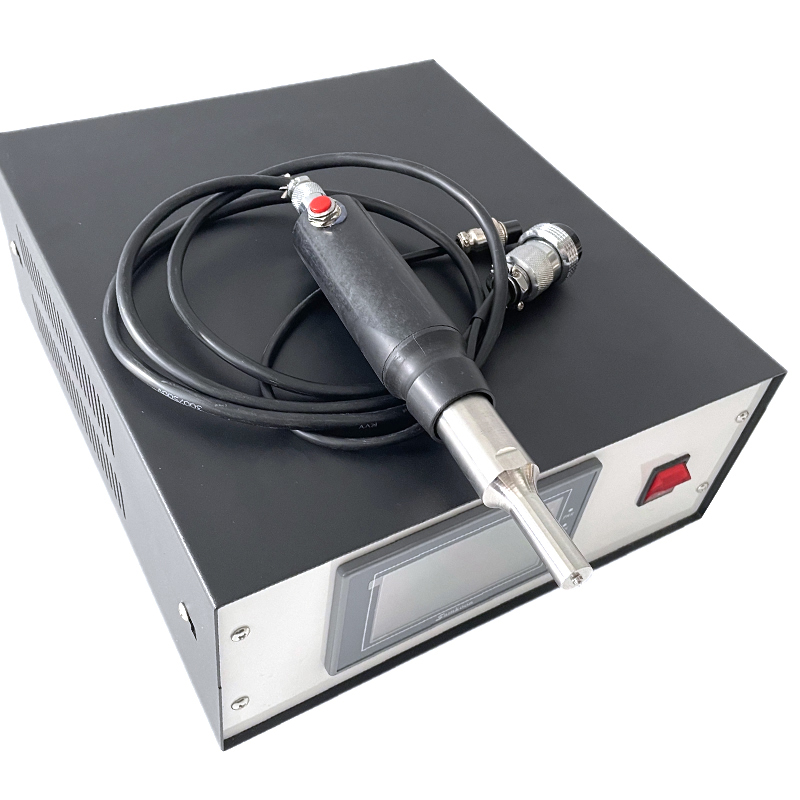

Compared to traditional processes such as adhesive bonding, prensado en caliente, o fijación con tornillos, handheld ultrasonic spot welding machines have significant advantages such as high production efficiency, Buena calidad de soldadura, protección del medio ambiente, y la conservación de la energía. La máquina de soldadura ultrasónica portátil también se puede utilizar para soldar, Remachado de productos termoplásticos, así como procesos de incrustación y prensado de cantos entre piezas metálicas y plásticas. It has completely replaced the process of organic melting point adhesive bonding, with characteristics such as low energy consumption, Alta eficiencia, sin deformación, Sin contaminación, Soldadura firme, y operación conveniente. Ultrasound can not only be used for welding metals, hard thermoplastic plastics, but also for processing fabrics and thin films. The handheld ultrasonic welding machine can replace different ultrasonic welding heads according to the size and welding requirements of the riveting points of the products to be welded. It is fast and convenient, and the cost is much lower than that of the specialized ultrasonic welding machine for car door panels, meeting the needs of customers.

Compared to traditional processes such as adhesive bonding, prensado en caliente, o fijación con tornillos, handheld ultrasonic spot welding machines have significant advantages such as high production efficiency, Buena calidad de soldadura, protección del medio ambiente, y la conservación de la energía. La máquina de soldadura ultrasónica portátil también se puede utilizar para soldar, Remachado de productos termoplásticos, así como procesos de incrustación y prensado de cantos entre piezas metálicas y plásticas. It has completely replaced the process of organic melting point adhesive bonding, with characteristics such as low energy consumption, Alta eficiencia, sin deformación, Sin contaminación, Soldadura firme, y operación conveniente. Ultrasound can not only be used for welding metals, hard thermoplastic plastics, but also for processing fabrics and thin films. The handheld ultrasonic welding machine can replace different ultrasonic welding heads according to the size and welding requirements of the riveting points of the products to be welded. It is fast and convenient, and the cost is much lower than that of the specialized ultrasonic welding machine for car door panels, meeting the needs of customers.

| Tipo | Poder(W) | Frecuencia (Khz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico -SKSONIC

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico -SKSONIC