Digital ultrasonic cleaning generators, as outstanding representatives of modern industrial cleaning technology, are gradually replacing traditional manual and chemical cleaning methods with their high efficiency, environmental friendliness, and precision. Its working principle is based on the cavitation effect of ultrasound in liquid, generating powerful micro jets and shock waves that can penetrate into small gaps of objects, effectively peel off and disperse stains, and achieve unprecedented cleaning effects.

Digital ultrasonic cleaning generators, as outstanding representatives of modern industrial cleaning technology, are gradually replacing traditional manual and chemical cleaning methods with their high efficiency, environmental friendliness, and precision. Its working principle is based on the cavitation effect of ultrasound in liquid, generating powerful micro jets and shock waves that can penetrate into small gaps of objects, effectively peel off and disperse stains, and achieve unprecedented cleaning effects.

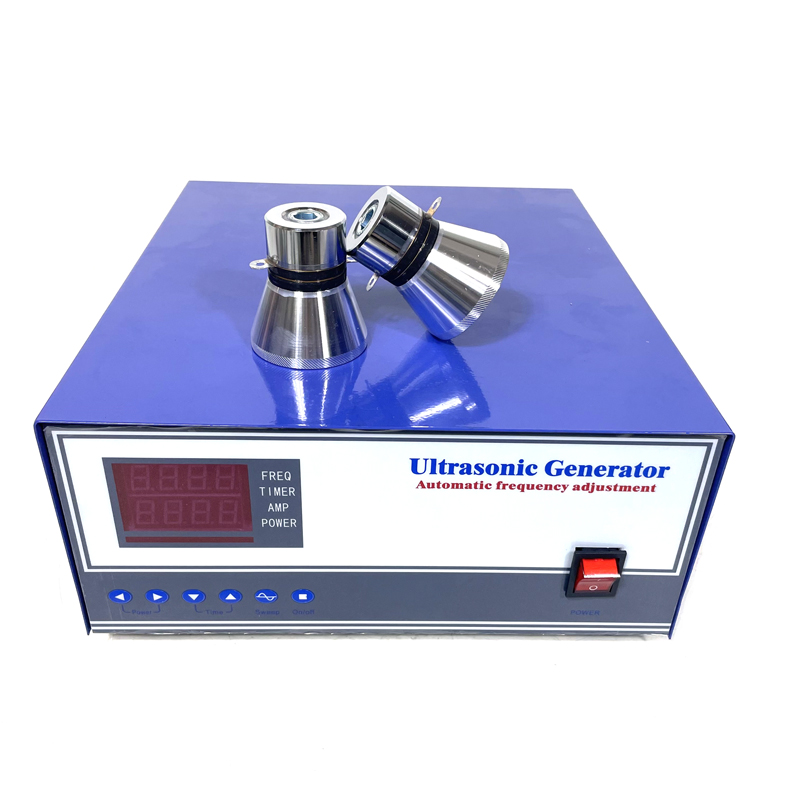

The digital ultrasonic cleaning generator is no longer limited to simple cleaning functions. It integrates advanced digital control technology, and users can accurately set the cleaning frequency, time, and temperature through a touch screen or remote control system to meet the cleaning needs of different materials and pollution levels. This intelligent operation mode not only improves cleaning efficiency, but also maximizes energy utilization and reduces operating costs.

The digital ultrasonic cleaning generator has also made significant contributions to environmental protection. Compared to traditional cleaning methods, it reduces the use of chemical cleaning agents and can even completely replace them in certain scenarios, greatly reducing the pollution of wastewater discharge to the environment. Meanwhile, efficient cleaning also means less energy consumption and longer equipment lifespan, promoting green production from the source.

The digital ultrasonic cleaning generator will continue to develop towards higher efficiency, intelligence, and environmental friendliness. With the integration and application of technologies such as the Internet of Things and big data, it will achieve more refined management and maintenance, bringing greater economic and social benefits to enterprises. We have reason to believe that in the near future, digital ultrasonic cleaning generators will become indispensable cleaning tools in various industries, leading industrial cleaning technology to a new height.

|

Type |

Power(W) |

Frequency (KHz) |

Transducer numbers |

Size |

|

AC110V60HZ+/-10% USA /LATIN AMERICA STANDARD ARE AVAILABLE |

||||

|

PU-GT300 |

300W |

20khz,25khz,28khz,33khz,40khz |

3-6 |

300x360x150 |

|

PU-GT600 |

600W |

20khz,25khz,28khz,33khz,40khz |

6-12 |

300x360x150 |

|

PU-GT900 |

900W |

20khz,25khz,28khz,33khz,40khz |

9-18 |

300x360x150 |

|

PU-GT1000 |

1000W |

20khz,25khz,28khz,33khz,40khz |

10-20 |

300x360x150 |

|

PU-GT1200 |

1200W |

20khz,25khz,28khz,33khz,40khz |

12-24 |

300x360x150 |

|

PU-GT1500 |

1500W |

20khz,25khz,28khz,33khz,40khz |

15-30 |

300x360x150 |

|

PU-GT1800 |

1800W |

20khz,25khz,28khz,33khz,40khz |

18-36 |

300x360x150 |

|

PU-GT2000 |

2000W |

20khz,25khz,28khz,33khz,40khz |

20-40 |

300x360x150 |

|

PU-GT2400 |

2400W |

20khz,25khz,28khz,33khz,40khz |

24-48 |

300x360x150 |

|

PU-GT3000 |

3000W |

20khz,25khz,28khz,33khz,40khz |

50-60 |

300x360x150 |

|

High Frequency |

300W-1200W |

65-80khz |

||

|

High Frequency |

300W-1200W |

120-135khz |

||